Connecting elements for structural steel construction

DIN EN 1090 describes the design of steel structures and aluminum structures, and Part 2 contains the technical rules for the design of steel structures. There, the use of high-strength bolts for steel construction is prescribed and the corresponding standards are also specified for this.

HV fittings for screw connections

HV is the designation of a bolted joint in steel construction with high-strength pretensionable bolts of strength class 10.9. H stands for high-strength (material property) and V stands for pretensioned (condition of the bolt). According to DIN EN 14399-4, HV sets are hexagonal bolts and -nuts that are standardized in the range M 12 to M 36. The associated washers are standardized in DIN EN 14399-6.

In summary, as an area of application, steel structures such as, among others, hall, bridge and industrial buildings, cableway installations and masts, high-voltage pylons and wind turbines.

The HV bolts are used in shear connections (shear-hole-bonded connections, slip-resistant connection in the serviceability limit state and slip-resistant connection in the ultimate limit state) and in tension connections (non-prestressed and prestressed).

Koelner products - Available in your desired dimension

You want our products in a certain size and dimension? Click on the article to go directly to the online store page.

What steel construction customers particularly appreciate about us

- Highest quality, because we do not compromise with our products. Tightening torques are responsible for the preload force, but this can only be maintained if the friction values are also determined correctly. Due to our high quality standards and our experience as one of the A suppliers in the automotive sector, we have the corresponding knowledge and equipment.

- Everything from a single source in brand quality: We provide you with a comprehensive steel construction product portfolio that is sure to leave nothing to be desired. This does not end with fasteners - tools and industrial safety materials round off our product range.

- Our steel construction team is ready for you: With your dedicated contact person, we always have your requirements in mind - supported by our own quality assurance department with 40 employees and an engineering and application technology department with 10 employees.

- Piece-precise construction site delivery - whether piece-precise delivery or deviating delivery address - we make both possible.

Quality criteria

HV bolts are safety-relevant and must meet strict quality criteria. The specified ratio of tightening torque to preload force ensures a high level of application safety. Strength class 10.9 bolts (with large width across flats) allow better utilization of bolt strength compared with normal steel bolts. Fewer bolts are required for the same frictional connection, or smaller HV bolts can be used, resulting in cost savings for all connections.

Mounting

There are two methods for achieving the defined preload force.

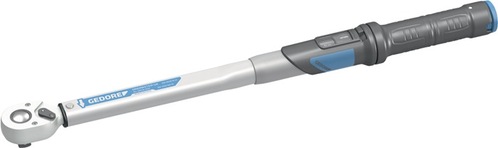

- The modified torque method (EN 1993-1-8), in which a defined torque is applied step by step by means of a torque wrench and thus the reduced preload force can be achieved.

- The combined pretensioning method (EN 1090-2), in which a defined pretensioning torque is first applied and then the nut is tightened at a defined further rotation angle. With this method, the full preload force is achieved.

The specified torques and angles can be taken from the assembly instructions, or from our practical HV calculation slider.

Important facts

- only complete sets (bolt, nut and washers) from one manufacturer may be used

- Ii a prestressed clothing is loosened, it must be replaced by a new one

- all screw sets must bear the CE mark (to be affixed to labels)

- the manufacturer of the HV bolted joints shall keep a copy of the certificate of conformity to the relevant standards, provide and confirm that the factory production control has been approved by a third party audit

- Documents confirming the quality of the set should be kept by the manufacturer and delivered at the request of the recipient within two working days

- HV bolts, nuts and washers must be protected from corrosion and contamination during storage

- HV screws are given a unique identification number and a guide number to ensure full traceability and easy access to detailed test results

Nord-Lock wedge-locking washers

Only Nord-Lock wedge-locking washers have building authority approval for all common screw connections in steel construction. Regardless of whether it is a preloaded or non-preloaded screw connection, HV, HR or SB screw connection, through-hole or blind hole or a threaded rod with nut.

Nord-Lock screw locking systems consist of a pair of wedge-locking washers with opposing wedge surfaces that interlock. This creates a wedge effect that prevents the screw from loosening. The wedge-locking washers utilise this effect and secure screw connections by increasing the clamping force instead of friction in order to develop their locking effect even under vibrations and dynamic loads.

In the event of relative movement in the screw connection, screws can loosen automatically due to their thread pitch. This can cause the components to fall apart or the screws to break. This is caused by impact or dynamic loads, vibrations, but also different temperatures.

Nord-Lock wedge-locking washers have been tried and tested for over 40 years and secure screw connections by increasing the clamping force instead of through friction. The wedge lock washers have wedge surfaces on the inside and radial ribs on the outside.

The shape of the wedge surfaces is selected so that the angle of the wedge surfaces "α" is always greater than the thread pitch "β".

The discs, which are glued in pairs, are inserted so that the inner wedge surfaces lie on top of each other.

Advantages:

- Effective anti-rotation lock in the event of impact loads or vibrations

- Quick and easy assembly/disassembly with conventional tools

- Same temperature properties as screw and nut

- Reusability

- High corrosion resistance (>1,000 hours salt spray, C4 long)

- Traceability through laser marking

HV locking sockets

The fuse sleeves are used in combination with HV fittings and enable one-sided installation. They are therefore suitable for installation situations that are difficult or inaccessible.

The connection is made by inserting the locking sleeve on the back of the fitting. Before welding the locking sleeve to the substructure, the corresponding nut or screw and a washer are inserted into the locking sleeve in the correct sequence and position. After welding to the structure, it can be protected against corrosion by powder coating or wet coating. Hot-dip galvanising or KTL coating may only be applied after consultation. Once the full tightening torque has been applied, the preload force creates a clamping effect that ensures a secure fit of the connection. When assembled, only the head and the collar are visible. Tightening torques can be found in the assembly instructions for our HV fittings.

Advantages

- Can be used for installation situations that are difficult to access

- Additional access structures, parts of the weld seam preparation and additional chamfering are no longer required

- Simplification of complex building constructions to create a more material-efficient and aesthetic component

- Closed structure of the HV locking sleeve on the nut or bolt head provides corrosion protection, which ensures the service life and performance of the bolted joint

Lindapter

The Lindapter product portfolio offers high-strength connections that can be made quickly by clamping two steel profiles together - without drilling and welding. Lindapter offers you a selection guide on the web so that you can always find the right solution for your specific application.

Fastening assortment

In order to connect steel structures to the existing building, you need connections that are approved for the various applications. Keller & Kalmbach offers you the right product for every application with the Fischer, Upat and FAKKT brands.

Tool & Equipment

In addition to design, assembly plays a major role. Without the right equipment, a smooth process cannot be guaranteed. Complementing the connection solutions, Keller & Kalmbach offers the right tools and equipment for every application.